When is the Right Time to Replace Your Dockboard?

Although dockboards are extremely durable, even the most well constructed units must periodically be replaced because of the wear and tear they are exposed to on a daily basis.

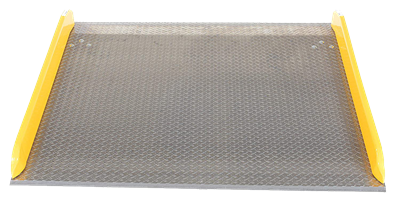

Raymond West supplies a variety of both steel and aluminum dockboards for your material handling needs. Our dockboard options are designed for years of safe and reliable use. Although dockboards are extremely durable, even the most well constructed units must periodically be replaced because of the wear and tear they are exposed to on a daily basis.

Dockboards that stay in service beyond their useful life can become a significant safety hazard. That’s why regular inspections are a must. Here are a few indicators that you may need to replace a dockboard:

Separating Side Curbs

While a dockplate is essentially a formed sheet of steel or aluminum, a dockboard has curbs attached to each side to prevent equipment from going over the edge while loading or unloading. These curbs also create more rigidity and add strength to the board.

Curbs are welded or bolted on, and after extensive use, welds can break and bolts can loosen or break. Curbs are integral to the capacity and weight distribution for a dockboard, and when they are compromised it can mean big trouble. When inspecting a dockboard, pay special attention to the curbs. Are there broken welds? Are there loose or missing bolts?

Flattening, Twisting or Warping

Although dockboards are extremely resilient, years of use can start to flatten or warp the metal. As lift trucks drive back and forth with heavy loads, the board is subjected to enormous forces that will eventually have a cumulative effect on the metal construction. Inspect your dockboard for signs of flattening, warping or twisting—these are indicators that you must replace the board. When a board is compromised in this fashion, the metal can start to develop stress fractures, which can result in a board breaking while it’s under load.

Compromised Fittings

Just as important as the dockboard itself are the fittings that hold your board in place while loading or unloading. When inspecting a dockboard, make sure that legs or locking pins are in good shape and not bent, broken or otherwise weakened. Look carefully at the bolts or welds that attach the legs. Likewise, be sure that locking pins (if equipped) are in good, operating condition.

Finally, check that forklift chains or lifting handles on your dockboard are secure. A heavy dockboard dropped while being placed can result in injury and equipment damage.

Dockboard Near Me

In the event you need to replace a dockboard, get in touch with a material handling expert at Raymond West today. We have a full range of both steel and aluminum options.