-

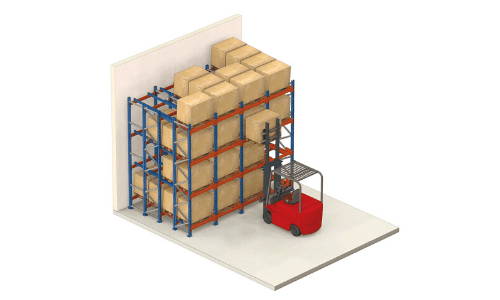

Push Back Rack allows you to gain pallet storage while eliminating aisles. This type of rack has the ability to double storage capacity, which can provide more picking faces, and can accommodate pallets of different sizes. The gravity-fed telescoping carts provide high density, multi-product storage.

Push Back Rack allows you to gain pallet storage while eliminating aisles. This type of rack has the ability to double storage capacity, which can provide more picking faces, and can accommodate pallets of different sizes. The gravity-fed telescoping carts provide high density, multi-product storage.

Each pallet is loaded onto a free-rolling carriage and as each additional pallet is loaded, it pushes the previously loaded pallet back further. As pallets are removed, the pallets move forward by way of gravity. Nesting carriages can store up to five pallets at a time.

-

Advantages:

- Eliminates unnecessary aisles

- Increased pick face locations

- Allows for selectivity and dense storage

- Sturdy construction

- Low maintenance

- Operational in freezers, coolers and high temperatures

- Roll-formed or structural

-

Applications:

- Multiple SKU inventory

- Pallets of different sizes

- LIFO (Last In, First Out) rotations

Ideal For:

- Food Distribution

- Cold Storage Warehouses

- High Volume Consumer Goods

Push Back Rack system is made up of two lateral tracks and different carts that slide inside of the push back structure. The first load (1) is placed on the top cart. The second load (2) pushes load (1) back far enough to reveal the cart below, which load (2) is rested on. The process continues.